HYDRAULIC CYLINDER

Hydraulic cylinder - what is it and how does it work?

Hydraulic cylinders are a design element of virtually any machine that needs to lift or move a large weight in a short period of time. These can include hydraulic cranes, excavators, dump trucks, front-end loaders and various other agricultural machines, robots on production lines and many, many others.

How does the actuator work?

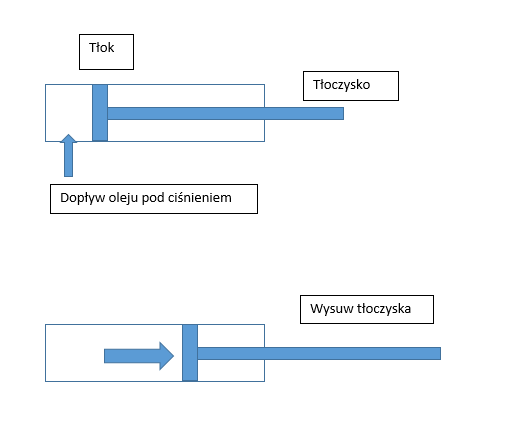

In vehicle hydraulics, the most commonly used actuators are piston cylinders. To imagine how they work, think of ... a syringe or after a feeder of silicone compound with which you seal a sink . The basic components of a piston actuator are the cylinder (body, housing), piston and piston rod. Oil is forced under pressure into the cylinder chamber, the pressure presses on the piston forcing the piston rod to extend.

Single-acting cylinder

This is how a single-acting actuator works. When the oil pressure stops, the piston rod stops. It descends when the oil returns to the tank. The extension and descent of the piston rod involves the use of a control. Thus, the task of a single-sided actuator is to apply a force acting only in one direction - it can, for example, lift the flap of a device, move an object, support an object in a given position for as long as needed.

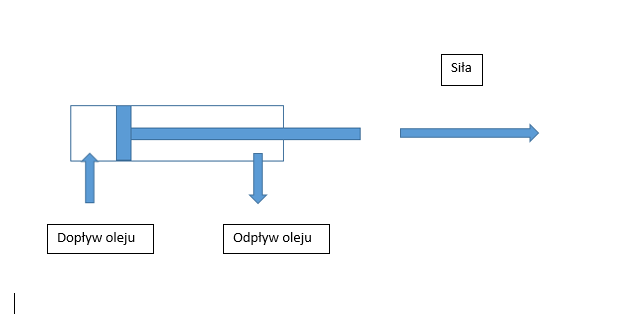

D ouble-sidedactuator A double-sided actuator is designed to perform movement in both directions. Therefore, there are two chambers in it that supply oil to the piston. The most typical application for a double-sided actuator is the controlled raising and lowering of objects by, for example, a hydraulic crane.

EXTENDING:

L OCKING

Telescopic actu ator

In order to increase the distance the piston rod can extend (the so-called working stroke of the actuator), telescopic technology is used - successive cylinders extending from each other are built into the actuator. In this way, the working stroke can be significantly increased.

Different types of actuators

The division outlined above is the starting point for a very large number of actuator variants. Single-sided actuators can, for example, have a diaphragm or plunger (an unsealed type of piston) instead of a piston rod. Double-sided actuators are sometimes equipped with two piston rods or several pistons. Custom versions can be many, but as a rule, the actuator is a device that is very simple in design, precise and durable. For those who are looking for information on how to select an actuator for a particular machine, how to install an actuator or what actuator failures may occur after prolonged use, please visit the following posts on the e-hydraulics blog.

Recommended

PENTA Hydraulic Cylinder L04L4, stroke 995, 5-11 t

Cylinder Penta LB065, stroke 1027, 6-12 T

Cylinder Penta L065, stroke 1252, 6-12 T

PENTA Hydraulic Cylinder LC066, stroke 1003, 6,2 t

Cylinder Penta LB066, stroke 1182, 6.2 T

Cylinder Penta L065Z, stroke 1432, 6-12 T

PENTA Hydraulic Cylinder L086, stroke 1726, 9,9 t

Cylinder Penta L085, stroke 1437, 9-17 T

Cylinder Penta L03S7, stroke 2209, 12-21 T

Cylinder Penta L03S6, stroke 1950, 15-25 T

Cylinder Penta L105, stroke 1586, 14-24 T

Cylinder Penta L02B8, stroke 1820, 14-24 T

PENTA Hydraulic cylinder L03B6

Cylinder Penta SB19, stroke 2229, 18-40 T

Cylinder Penta AL03B7, stroke 1613, 12-21 T

Cylinder Penta AL105 , stroke 1615, 12-21 T

Cylinder Penta L04/475/3, stroke 1043